Coolants: a highly complex structure and ingredients

Lesezeit: 5 Min. | 15.03.2017

Content

Whereas formerly the main focus was on the technical performance of coolants, compatibility with people is becoming an ever greater priority.

In addition, there are numerous and sometimes contradictory requirements relating to coolants that mean products can have 15 to 25 individual constituents. However, this wide variety of mixtures can lead to problems, as various limit values and restrictions must be observed when selecting a raw material for a suitable product formulation. In turn, this leads to a significant reduction in the range of raw materials available. Therefore, in many cases substances that are much purer must be selected, despite the correspondingly higher raw material costs.

Challenges in compiling coolants

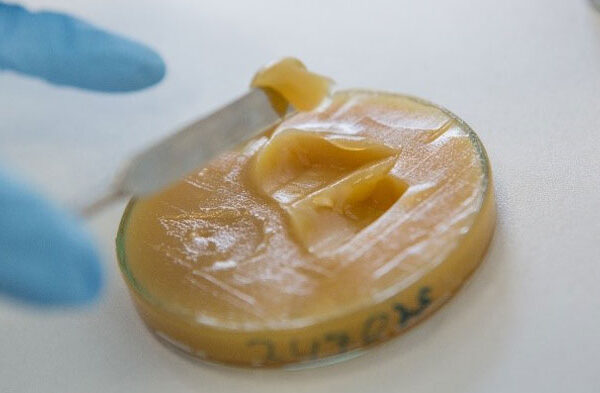

With water-miscible coolants, the challenge is bringing the main component, oil (or alternative lubricants), into a stable relationship with water. The decisive factor in this task is emulsifiers, which lower the surface tension between the oil phase and water phase to enable a distribution of the oil droplets in the water. The emulsifier is therefore a crucial link in the emulsion for a coolant to function as intended.

To protect the emulsifier system for as long a retention time as possible, various additives are added to the water-miscible coolant. Other additives are used to strengthen the specific performance properties.

Neat oils only require a few individual constituents, as the influential parameters levied by water do not apply. A fundamental component of neat oils is oil. To improve the material cutting performance, the oil is enriched with polar substances and chemically-acting EP additives. Other additives such as anti-fog additives or inhibitors improve the durability and behaviour of the neat oils in the machining process.

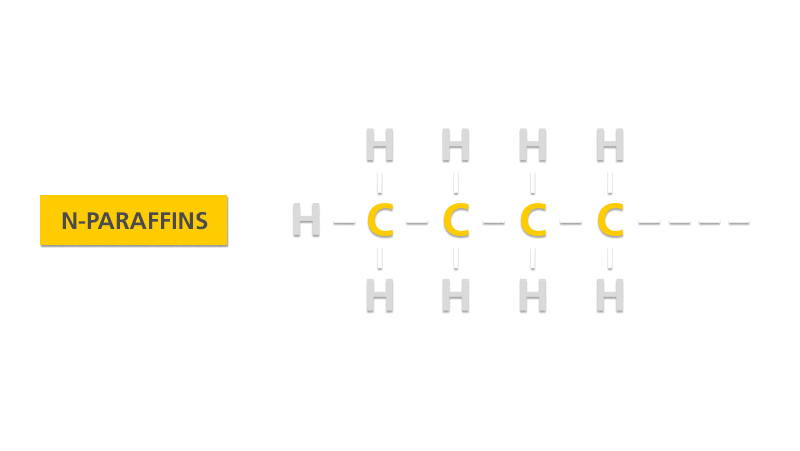

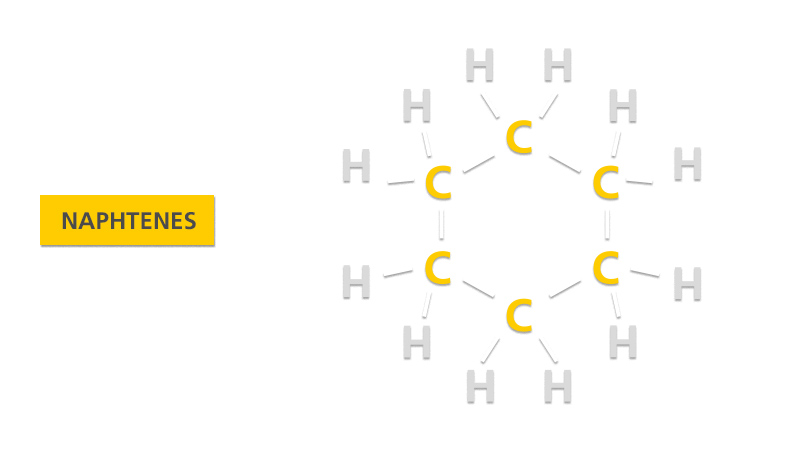

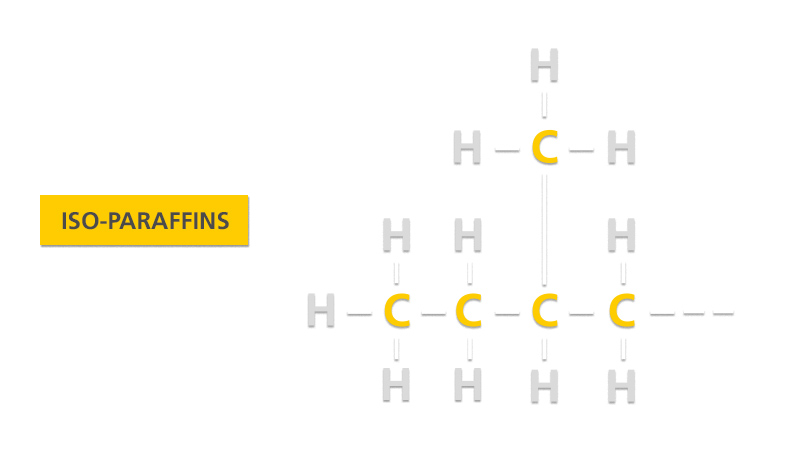

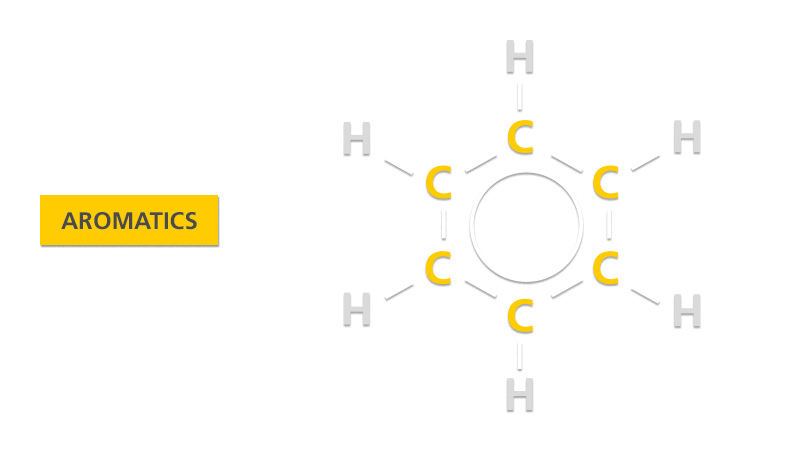

Mineral oils are still used as base fluids for machining lubricants in around 65 to 70 percent of cases. But there are also extremely effective alternatives to mineral oils