We take responsibility for our environment – by adopting specific measures aimed at achieving comprehensive sustainability. We do our bit to ensure that future generations can also look forward to a liveable future on our planet. This is an integral part of how we do business – and a core belief of Rhenus Lub and its partners.

Our journey towards greater sustainability

Our commitment to sustainability

We’re united by sustainable ideas. Across the generations for people, machines and the environment. Versatile and multifaceted as the basis of our company philosophy.

- Resource-efficient production is of the utmost importance to us – with carefully selected raw materials that have a decisive influence on the reduction of emissions in production, use and disposal.

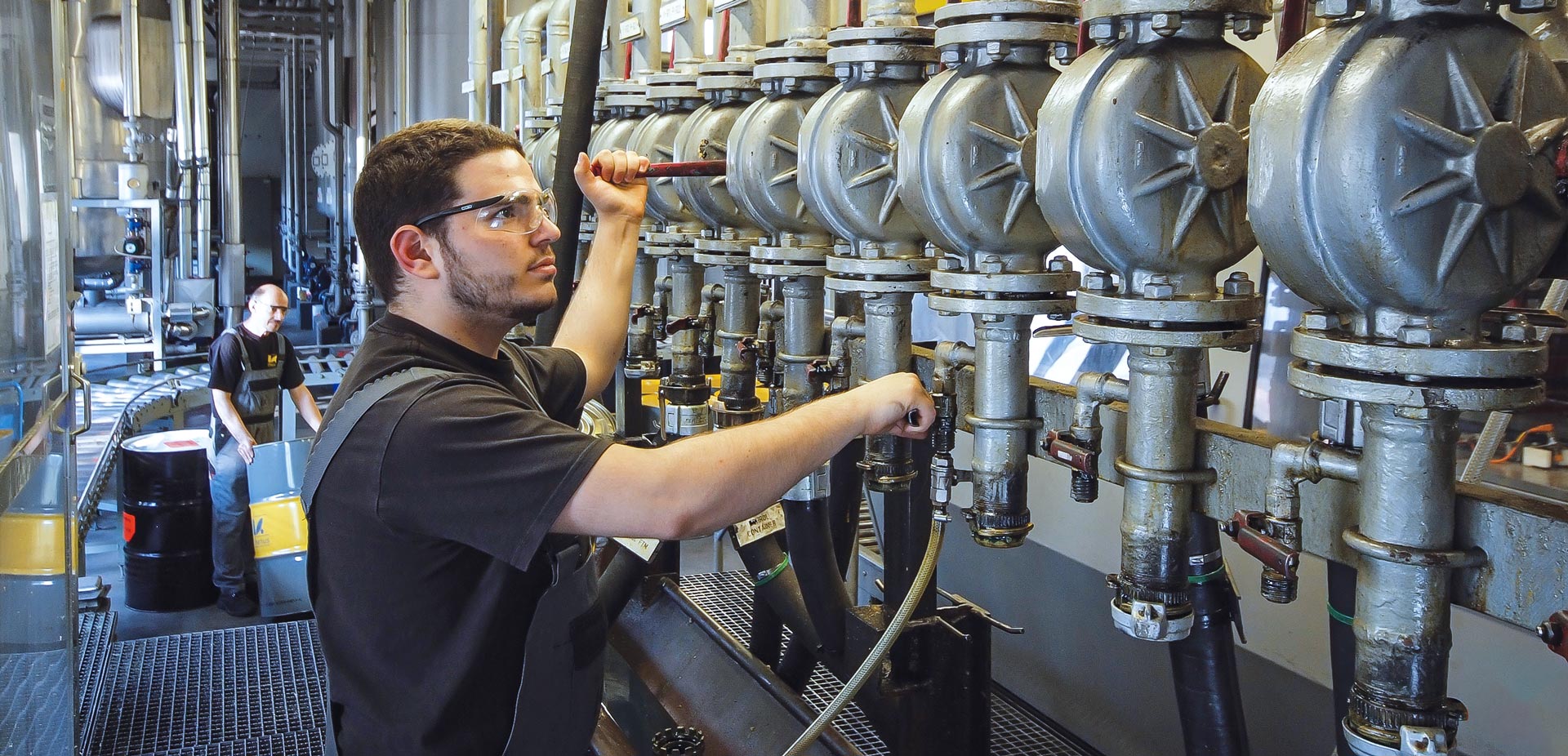

- We stand up for safe working conditions and hence offer metalworking fluids that are free of amines and boric acid – and therefore especially kind to the skin.

- In our research and development, we’re committed to sustainability as a driver of innovation. We’re therefore testing metalworking fluids that contain plant-based base oils and bio-based additives.

- We stand up for greater sustainability in industrial applications. With our biodegradable greases, environmental protection is child’s play – and certified according to DIN CEN/TR 16227.

- We provide support on the ground with funding projects that prioritise social commitment, particularly when it comes to offering young people the prospect of a brighter future.

- We set ourselves measurable targets, confirmed by the Science Based Targets initiative (SBTi)

Our targets in accordance with the Science Based Targets initiative (SBTi)

Our commitment to sustainability is underpinned by transparency and measurability. One key step in this direction comes in the form of our targets for reducing greenhouse gas emissions, which have been confirmed by the SBTi.

Summary of objective: in the short term, 1.5°C by 2030

This objective was approved as part of a simplified target-validation procedure that is only applicable to small and medium-sized enterprises (SMEs). Rhenus Lub GmbH & Co KG is committed to reducing scope 1 and 2 greenhouse gas emissions by 50% by 2030 – relative to the base year 2018 – and to measuring and reducing its scope 3 emissions.

About the Science Based Targets initiative

The Science Based Targets initiative (SBTi) is a collaboration between the Carbon Disclosure Project (CDP), the United Nations Global Compact (UN Global Compact), the World Resources Institute (WRI) and the World Wide Fund for Nature (WWF) and constitutes one of the commitments of the We Mean Business Coalition. The initiative advocates the establishment of scientifically sound objectives in order to bolster the competitive advantage of companies during the transition to a low-carbon economy.

Science-based targets are targets for reducing greenhouse gas emissions in line with the degree of decarbonisation needed to reach the objectives of the Paris Agreement – to limit global warming to well below 2°C above pre-industrial levels and to pursue efforts to limit warming to 1.5°C.

UN Global Compact: sustainable and fair

The Global Compact initiative of the United Nations aims to develop a sustainable and fair economy. As a long-standing member of the initiative, we are also committed to that objective. We act responsibly and stand up for human rights, labour standards, environmental protection and the fight against corruption. Of course, we see the UN’s Sustainable Development Goals as an integral part of these efforts.

100 per cent green electricity: double support for the energy transition

We’ve relied on green electricity for many years and will continue to follow this path. In fact, since 2019, we’ve used entirely “genuine,” certified green energy.

The power for our production processes and infrastructure is generated entirely from renewable energies. It is produced in an environmentally friendly and sustainable manner – and precisely when we need it. The electricity flows directly to us from the European grid without the use of complex storage equipment.

We’re therefore making a double contribution to the energy transition: by drawing electricity directly and through the price surcharge for green electricity, 75 per cent of which goes into new systems for renewable energies.

Not all green electricity is the same

We rely on 100 per cent genuine green electricity derived from renewable energies. The generation process also relies entirely on pure green electricity – and green power is even used to produce the necessary components.

This makes a big difference. After all, electricity is only genuine green electricity if the entire process is sustainable and environmentally friendly – from production to disposal. It’s also vital that production and consumption take place simultaneously. Certainty in this regard is provided by certificates according to standards such as TÜV Süd EE02 (CIVIS Standard EE+ with the CMS Standard EE02 list of criteria).

Reusable and recyclable reconditioned drums for our world of tomorrow

We fill many of our metalworking fluids in steel drums – and here we rely on reconditioned drums. These drums can not only be reused up to 10 times, but can also be recycled afterwards. This results in considerable savings in raw materials and an efficient contribution to the circular economy.

In addition, the use of reconditioned packaging reduces emissions of CO2 and other greenhouse gases by up to 80% compared to new packaging. In 2023, we were already able to save more than 870,000 kg of CO2 by using over 40,000 reconditioned drums.

Measurable sustainability

We work with independent institutions to ensure clarity. Here, the product carbon footprint (PCF) and corporate carbon footprint (CCF) play a central role. We take a transparent and data-led approach to determining the emissions that are ascribed to the product and the company. We analyse in order to optimise – and always with a view to achieving even greater sustainability overall.

How are our company’s emissions calculated?

The calculation of our company’s emissions is based on the Greenhouse Gas Protocol. Account is taken of various emission types, including not only the direct greenhouse gases from our own energy systems but also emissions produced indirectly (in supplying energy to the company). Other indirect emissions also arise throughout the value chain.

Sustainable production: corporate carbon footprint (CCF)

As a company, we’re working step by step to improve our sustainability. We use the corporate carbon footprint to document our journey. In order to reduce the CCF on a long-term basis, we’re already taking numerous steps to achieve emissions savings.

Sustainable products: product carbon footprint (PCF)

How much CO2 does a product give rise to? We work with an independent institute and our partners along the supply chain to determine the exact carbon footprint for selected products in our portfolio. An important benchmark for greater comparability.