Whether it’s with metalworking fluids, lubricating greases or fluid management, Rhenus Lub has you covered. You’re always on the safe side with our products and services.

22600

270

100

109

Impuls News

Latest articles and technical data sheets on metalworking lubricants, special greases and new research results from Rhenus Lub.

Find out more now!

Why Rhenus Lub?

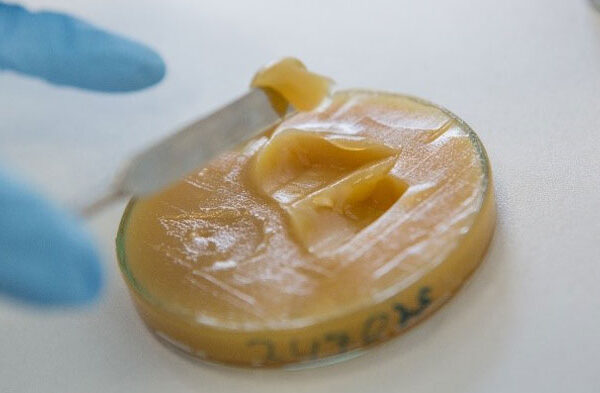

Metalworking Fluids

You’re sure to find your optimum solution within our comprehensive range of metalworking fluids.

Lubricating Greases

Our special greases contribute to the success of components and systems in all branches of industry.

Fluid Management

We provide you with selected fluid-related services – or take over your complete fluid management. Expertise and experience help deliver optimum processes.

Responsibility

Performance, safety and environmental protection are not mutually exclusive when it comes to our products.

For easy handling and satisfied employees.