rhenus machining oils based on gas-to-liquid (GTL) technology deliver maximum purity and service with a good price-performance ratio.

New possibilities with GTL technology from Rhenus Lub

Enjoy all the benefits of this complete, high-performance package.

Environment

Environmental compatibility and low disposal costs thanks to maximum oil purity

Safety

No risks during changeover: our tried-and-tested on-site service supports you throughout the entire process with guaranteed fail-safe operation for your production

Process

Long tool life, reduced wear and maintenance costs, excellent cooling effect and optimum flushing

Cost savings

Reduced consumption thanks to long service life and minimal evaporation

Health

Free of chlorine, aromatic hydrocarbons and heavy metals, high flash point (>200°C) and minimal mist formation

Handling

Low viscosity, excellent foaming behaviour, high flash point

Boost performance and reduce costs with rhenus GTL technology. All information is available to download as a brochure.

Possible solutions

rhenus professional GTL oils provide an effective combination of performance, innovation and safety.

Frequently asked questions

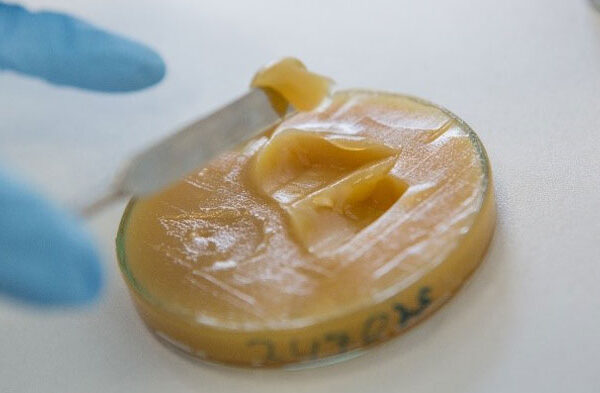

Take your production to a new level on a lasting basis with the rhenus EHM 12 and rhenus EU 12 professional grinding oils, which are based on innovative GTL technology.

Are there any differences between GTL oils?

GTL oils are what are known as hydrocracked oils. Depending on their formulation, GTL oils can differ from one another. rhenus GTL oils exhibit excellent foaming behaviour and very high lubrication performance. This prevents wear, increases service life and makes the process altogether safer – resulting in significant cost reductions.

What do GTL oils from Rhenus Lub offer?

Thanks to their formulation and special properties, rhenus GTL machining oils offer numerous advantages for users:

- high flash points (over 200°C)

- favourable anti-fog behaviour

- a high level of occupational health and safety

- effective reduction in fire risk

- extended tool life, additional cost savings

- very high lubrication performance

- excellent foaming behaviour, reduced tool wear

- clean machine tools thanks to good rinsing properties

- low evaporation losses and economical use.

Impuls News

The latest posts and expert articles relating to metalworking fluids, special greases and new research findings from Rhenus Lub.