rhenus FluidSafe: un sistema de medición único en el mundo para su lubricante refrigerante. Diseñado para la medición totalmente automatizada y en tiempo real de los cuatro parámetros más importantes de los lubricantes refrigerantes, con el fin de que pueda disfrutar de un control seguro y preciso de sus procesos.

rhenus

FLUIDSAFE

Dé la bienvenida a la industria 4.0

La calidad del lubricante refrigerante es un factor decisivo para lograr un proceso de fabricación de éxito. rhenus FluidSafe le permite supervisar continuamente y en tiempo real los siguientes parámetros:

- Concentración

- Valor pH

- Conductividad eléctrica

- Contenido de bacterias

El sistema se puede integrar totalmente en sus procesos de industria 4.0 y garantiza un aprovechamiento óptimo de los recursos.

Solicite una revisión de lubricantes refrigerantes y consulte a nuestro equipo las ventajas para su producción.

Más información acerca de la revisión de lubricantes refrigerantes

En la revisión de lubricantes refrigerantes le atendemos en sus instalaciones. Nuestros expertos ponen al descubierto los potenciales de optimización y le ofrecen un asesoramiento exhaustivo sobre todo lo relacionado con los lubricantes refrigerantes.

Medición moderna del

lubricante refrigerante

de vanguardia para conseguir

una fabricación moderna

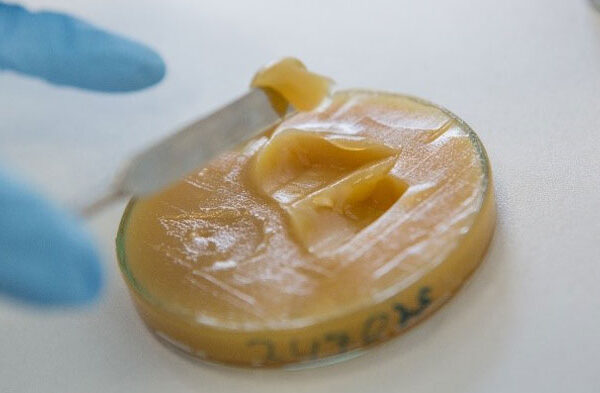

Supervisar los lubricantes refrigerantes supone un importante gasto de personal y costes. Las revisiones periódicas con distintos dispositivos de medición, como refractómetros o laminocultivos de inmersión, así como la documentación correspondiente desvía recursos de su proceso principal.

Los resultados y las medidas que de ellos se derivan suelen llegar tarde y no ser eficientes.

FluidSafe LubControlSystem, un sistema totalmente automatizado, se encarga de supervisar los parámetros continuamente, con lo que facilita una intervención y una corrección tempranas, por ejemplo, frente al crecimiento exponencial de bacterias.

Sus ventajas de un vistazo

Supervisión continua, calidad constante del lubricante refrigerante

Totalmente automatizado y transparente, gracias a los valores de referencia

Umbrales de intervención bajos para aplicar correcciones

Lubricantes refrigerantes fiables y estables

Vida útil prolongada de los fluidos

Menor consumo de concentrados y estabilizadores

Ahorro de recursos

Mejoras de rentabilidad

Todos nuestros servicios relacionados con lubricantes refrigerantes

¿Preguntas?

¡Póngase en contacto con nosotros!

Impuls News

Nuevas publicaciones y artículos especializados sobre lubricantes refrigerantes, grasas especiales y nuevos hallazgos de la investigación en Rhenus Lub.