Whether gun drilling, gear hobbing or machining highly alloyed metals — in many manufacturing operations, users are confronted with intense friction and increased wear as a result of high pressures. The use of coolants with EP additives helps to effortlessly overcome these challenges.

Effective under high pressure

The active ingredients behind EP additives have been established as important components of various high-performance coolants. They improve the tribological properties of these products, partly by increasing the load-bearing capacity and partly by reducing tool wear. The name itself even indicates that the additives are intended for use under enormous pressure loads: EP stands for “Extreme Pressure” and thus means that lubricants containing EP additives are ideal for operations in which high pressures are commonplace.

Workpiece and tool free from welding

The use of EP additives ensures that the metal surfaces of the workpiece and the tool that move against each other sustain as little damage as possible, even under extreme loads, while actively preventing welding of the friction contact points on the two surfaces at the same time. Typical EP additives include sulphur, phosphorus, zinc, nitrogen and other compounds.

Various theories on the mode of action

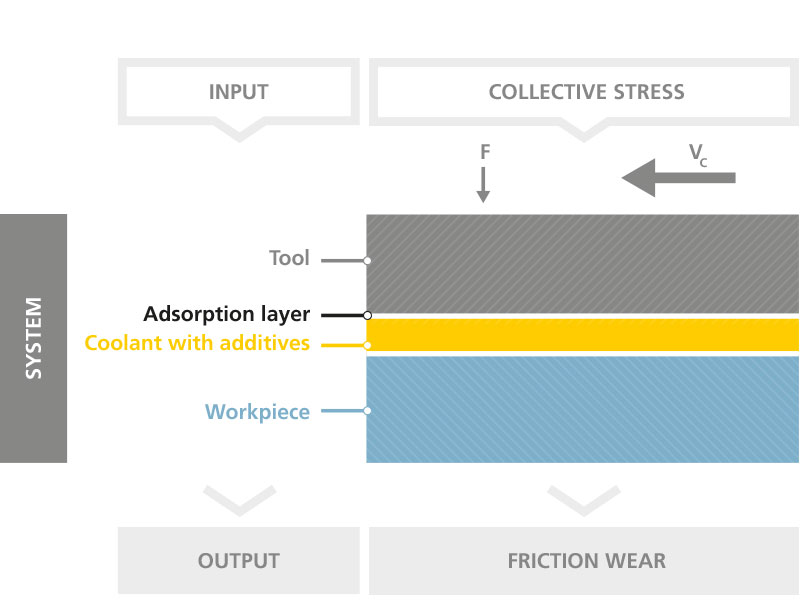

There are several theories regarding the mode of action of EP additives, such as the microcrack, reaction layer or adsorption layer theory. With the adsorption layer theory (see graphic), for instance, the coolant containing EP additive forms a layer on the surface of the material, which protects the workpiece even during machining under high-levels of pressure and minimises friction.

Tribological system

Lubricants with EP additives from Rhenus Lub

The range of products offered by Rhenus Lub includes a number of coolants containing EP additives that demand the highest level of strength and endurance. Please do not hesitate to contact us to discuss specially designed applications designed for your production process. We can help you choose the right product for you.