EU Ecolabel (EEL) for rhenus LAE 2 high-performance biolubricant

Reading time: 5 Min. | 04.12.2023

Certified environmental compatibility with high performance: Rhenus Lub receives EU Ecolabel (EEL) for rhenus LAE 2 high-performance biolubricant

- Developed on biodegradable synthetic base oils

- Increases performance and environmental compatibility

- Suitable for total loss lubrication even under high loads

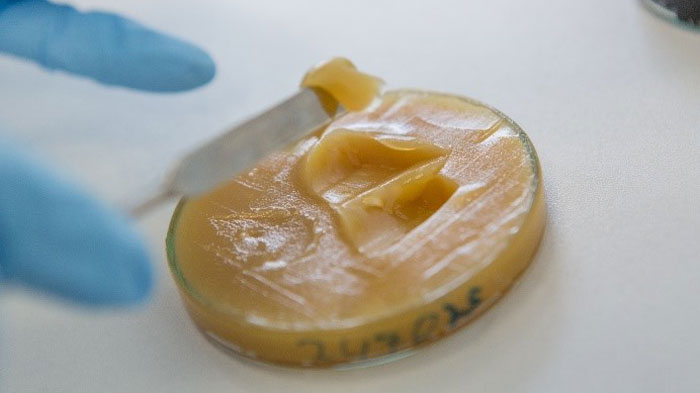

Standard mineral oil based greases often have very high performance, but can potentially pose a risk to the environment, depending on the application and handling. Rhenus Lub has therefore been investing considerable resources in research and development for many years to make its products particularly environmentally friendly. The newly launched rhenus LAE 2, a further development of the proven rhenus LAC 2 biolubricant, has been awarded the EU Ecolabel (EEL) following an extensive certification process. The EEL is recognised in all member states of the European Union as well as in Norway, Liechtenstein and Iceland. It is awarded to products that have a low environmental impact throughout their life cycle.

“Native base oils from rapeseed or sunflowers are susceptible to oxidation and therefore often not suitable for demanding applications. This has led to prejudices about the performance of biogreases,” explains Dr Marco Pfeiffer, Head of Product Management & Sales Greases at Rhenus Lub. “We set out to change this view. Thanks to synthetic esters with excellent properties, such as those used in rhenus LAE 2, biolubricants are now just as efficient as mineral oil based lubricants in many areas. Although the Ec olabel only allows very limited applications, we have succeeded in developing an extremely high performance solution. In terms of performance, there is hardly any comparable product in Ecolabel greases at the moment we are at the forefront of development here.”

Strict criteria for the award of the European Ecolabel

EEL certified products have a lower impact on air, water, soil and human health than commercially available mineral oil based lubricants. In order to obtain the EEL certificate, companies must satisfy strict criteria. These include among other things compliance with the Lubricant Substance Classification (LuSC) list which specifies the raw materials that can be used. At the same time, the use of “performance raw materials” that are usually not biodegradable or biodegradable to only a limited extent, is restricted. In addition, there are regulations for the packagings that must contain a certain percentage of recycled material and be designed in such a way that spillage is reliably prevented.

Reliable performance in critical situations

The rhenus LAE 2 high-performance biolubricant has been optimised above all for use at total-loss lubrication points where excess and displaced grease can get into the soil, the sewage system or into rivers or lakes. These include, for example, construction machinery, machines and transport equipment in overburden and mining areas, equipment in hydraulic engineering, lock, sewage treatment and port facilities, agricultural machinery or rail transport. While mineral oil-based lubricating greases always pose a certain risk to the environment here, rhenus LAE 2 is easily biodegradable. It is suitable for the lubrication of antifriction and plain bearings under high – even impact – loads and reliably withstands high temperatures. In addition, it is resistant to water and oxidation, has very good anti-corrosion and good adhesion properties.

“The further development and optimisation of our proven biolubricant and the certification of rhenus LAE 2 with the EU Ecolabel are further steps on our road to wide-scale sustainability,” says Dr. Marco Pfeiffer. “We are already in the process of bringing further products to market and will continue to proactively drive the issue forward in the future.”

rhenus LAE 2: advantages at a glance

- Manufactured on the basis of synthetic high performance esters

- Certified with the EU Ecolabel (EEL)

- Biodegradable

- Resistant to oxidation and water

- High shear stability and pressure absorption capacity

- Very good corrosion protection properties

- Good adhesion properties