Full control at high pressures – with no foam

Reading time: 4 Min. | 14.11.2019

How coolant rhenus TS 421 effortlessly masters general machining and grinding operations

High pressures are part and parcel of manufacturing processes for many metal processors – and this is likely to increase. This also poses a challenge for coolant developers. Not only do the fluids used need to be very efficient, they also have to curb foam build-up. Foam directly impacts the performance of the emulsion. The consequence: Its isolating effect compromises the cooling of the tool cutting edge. But which coolant is recommended for these conditions? The answer is rhenus TS 421.

The coolant offering improved cooling and lubrication

rhenus TS 421 from Rhenus Lub is among the products on the market generating the least amount of foam. Developed for the most common machining and grinding processes, the water-miscible coolant virtually generates no foam at all at high pressures. This enhances the cooling and lubricating effect. “This is a key factor for success for users. The low foam production and the good rinsing properties of rhenus TS 421 have a direct impact on process costs. As we don’t allow foam to build up in the first place, the hardness of the mixing water only plays a subordinate role. This is beneficial for manufacturing companies who want to have the best conditions for foam-free machining with soft water,” says Daniele Kleinmann, Head of Product Management for Coolants at Rhenus Lub.

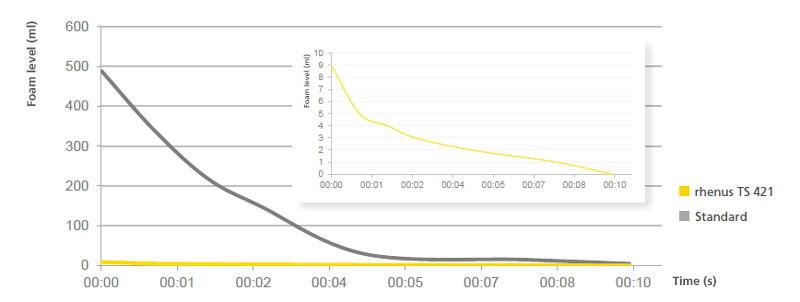

Foam degradation

Compared to conventional products, rhenus TS 421 reduces foam build-up by more than 90%.

rhenus TS 421 also offers a number of other benefits:

The water-miscible coolant has excellent long-term stability and is robust – it does not contain any conventional preservatives thanks to its alternative formulation. “This allows us to make the manufacturing processes of our customers safer,” says Daniele Kleinmann, outlining the additional benefits of the water-miscible coolant.

The low-foam coolant rhenus TS 421 guarantees excellent cooling and lubricating properties from the outset.

Manufacture more efficiently with rhenus TS 421

Users admire rhenus TS 421 for the combination of attractive performance values and cost-optimised production. Steel and cast iron pose no problem at all. Aluminium can also be machined. It is also suitable for the most common machining operations, such as grinding, swivelling, drilling or milling. Not only is manufacturing with rhenus TS 421 simple, it is also efficient, as Daniele Kleinmann explains: “rhenus TS 421 can be relied on to cover common machining operations and thus helps to save costs.” Its stable formulation also greatly reduces maintenance requirements and keeps the process stable over the long term.

rhenus TS 421 can be relied on to cover common machining processes and thus helps to save costs.

How can users control foam build-up?

Two factors in particular stand out. The first is that foam build-up depends on the hardness of the water used. Soft water tends to generate more foam. The second is that there are coolants that have been developed to generate less foam. Products that generate less foam from the outset therefore offer a key advantage.

rhenus TS 421 – das Wichtigste auf einen Blick

- Exceptionally low maintenance

- Stable over the long term – with no critical preservatives

- Efficient thanks to its attractive price-performance ratio

- It can be used for general machining and grinding steel, cast iron and aluminium

- Excellent cooling and lubrication thanks to extremely low foam generation

- Impressive in terms of environmental protection – classification in water hazard class 1 (WGK 1)