High-flyer and all-rounder: Manufacturing aircraft components more efficiently

Reading time: 5 Min. | 25.06.2020

Content

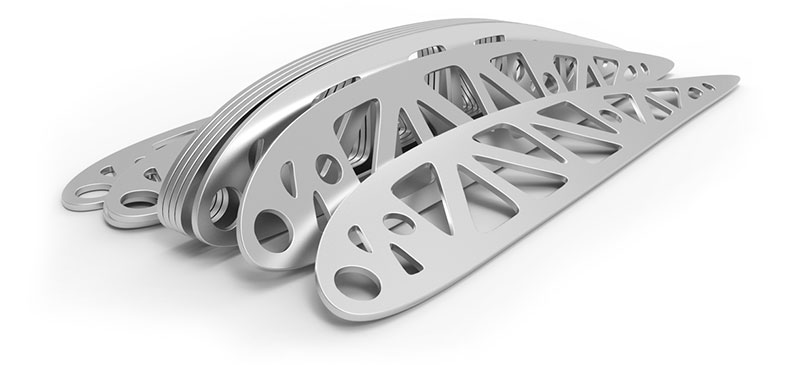

Coolant rhenus TU 43 P performs optimally with materials that are difficult to machine and has numerous aviation approvals

Aircraft manufacturers and suppliers of aircraft components are well aware: The high-strength materials used in aircraft construction are particularly challenging to machine. Using the correct machining fluid plays a decisive role. Lubricant expert Rhenus Lub has the perfect solution – its special coolant rhenus TU 43 P. Approved for aviation by renowned manufacturers including Airbus, Safran and Bombardier, rhenus TU 43 P ensures excellent component quality. The special coolant impresses with long tool life and facilitates a smooth, more cost-effective machining process. It not only plays a leading role in the aircraft sector but has also proven itself as a real all-rounder in many other industries with a similar range of materials.

Perfect performance and efficient machining:

rhenus TU 43 P prevents staining of sensitive components.

Staying cool at maximum performance: Quality assurance in aircraft construction

Aircraft elements push machine tools to their limits. Coolant rhenus TU 43 P, developed for a broad range of materials, rises to this challenge. As a true all-rounder, it helps users to find the optimal balance between service life, process safety and machining time, specially tailored to highly challenging machining in the aviation industry. In concrete terms, it enables high cutting and feed rates with optimal cooling and improved tool quality.

A practical example also demonstrates the process-optimising performance of the special coolant: “When Inconel is turned, the service life of the carbide inserts used was increased by 50 percent, resulting in a significant reduction in tooling costs,” says Daniele Kleinmann, Director of Product Management for Coolants at Rhenus Lub. Another property of the special coolant that adds to its cost-effectiveness is its low additive concentration: Levels below 2 percent are quite common. Furthermore, users benefit from its very stable emulsion service life of more than one year. The numerous aviation approvals for rhenus TU 43 P act as an important assurance for suppliers to the aviation industry.

The all-rounder coolant for cross-sectoral applications

Besides being used in aviation, rhenus TU 43 P also impresses in other sectors when it comes to process optimisation, wherever grinding, turning, drilling, milling or thread machining of steel, stainless steel, aluminium or titan is the task at hand. For example, rhenus TU 43 P optimises machining operations in the automotive, mechanical engineering and steel machining industries.

Good to know: The lubricant specialists at Rhenus Lub deliberately took environmental protection and occupational safety into account when formulating the product. “rhenus TU 43 P does not contain any components from the SVHC list, has good skin compatibility and is easy to handle thanks to its water hazard class 1,” says Jörg Kummerow, Head of Global Customer Development at Rhenus Lub. With its outstanding rinsing properties, rhenus TU 43 P guarantees clean machines, tools and workpieces, reducing the amount of cleaning required.

Coolant rhenus TU 43 P – its use at a glance

- Materials: predominantly aluminium such as EN AW 7075, EN AW 6082, as well as titanium and stainless steels

- Application areas: Machining centres, turning/milling centres, turning machines, grinding machines

- Usage concentration: between 6 and 10%

- Very low replenishment concentration down to below 2% possible