rhenus EU 12-O – high process reliability, reduced costs

Reading time: 6 Min. | 25.05.2023

New high-performance grinding and cutting oil proves its worth as an alternative in the automotive industry

Lubricants for the automotive industry have to meet stringent demands, delivering maximum performance and process reliability while ensuring low consumption and the smallest possible burden on humans and the environment. Our new high-performance grinding and cutting oil rhenus EU 12-O has demonstrated its capabilities in a practical test at one of the world’s largest automotive suppliers.

Pioneering GTL oil

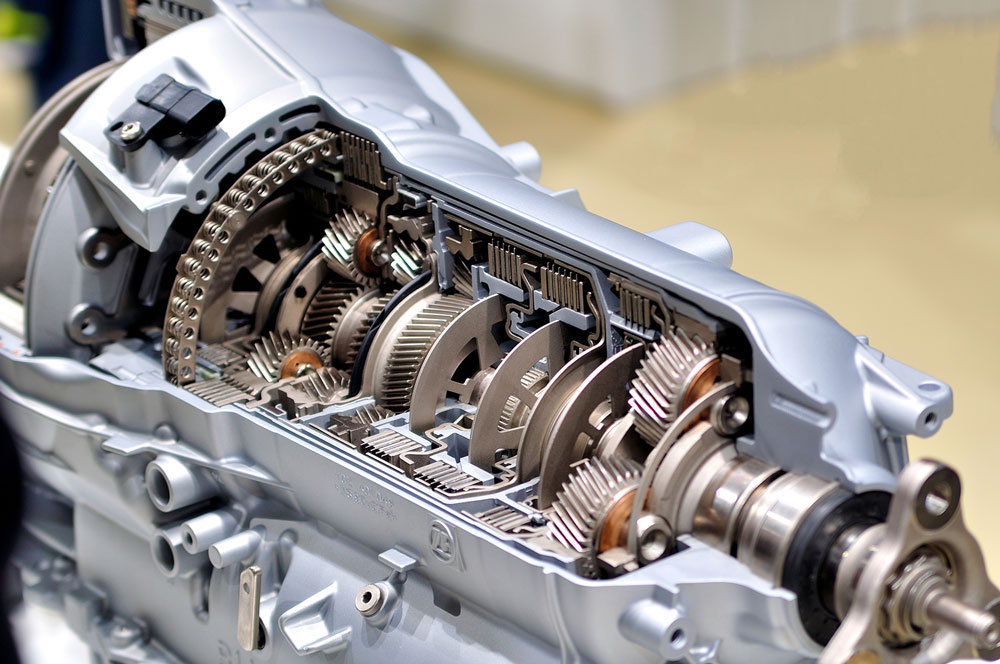

rhenus EU 12-O is based on pioneering gas-to-liquid (GTL) technology. The machining oil has a very narrow boiling range, is free of aromatics and odourless, and impresses with its improved lubrication performance and optimised foaming behaviour. This universal, high-performance grinding and cutting oil is suitable for challenging tasks such as the grinding of carbide metals and gear components as well as the machining of special alloys. As such, it is an ideal alternative to the conventional mineral oil-based lubricants that are still commonly used – above all in the automotive industry.

Stable performance in challenging grinding processes

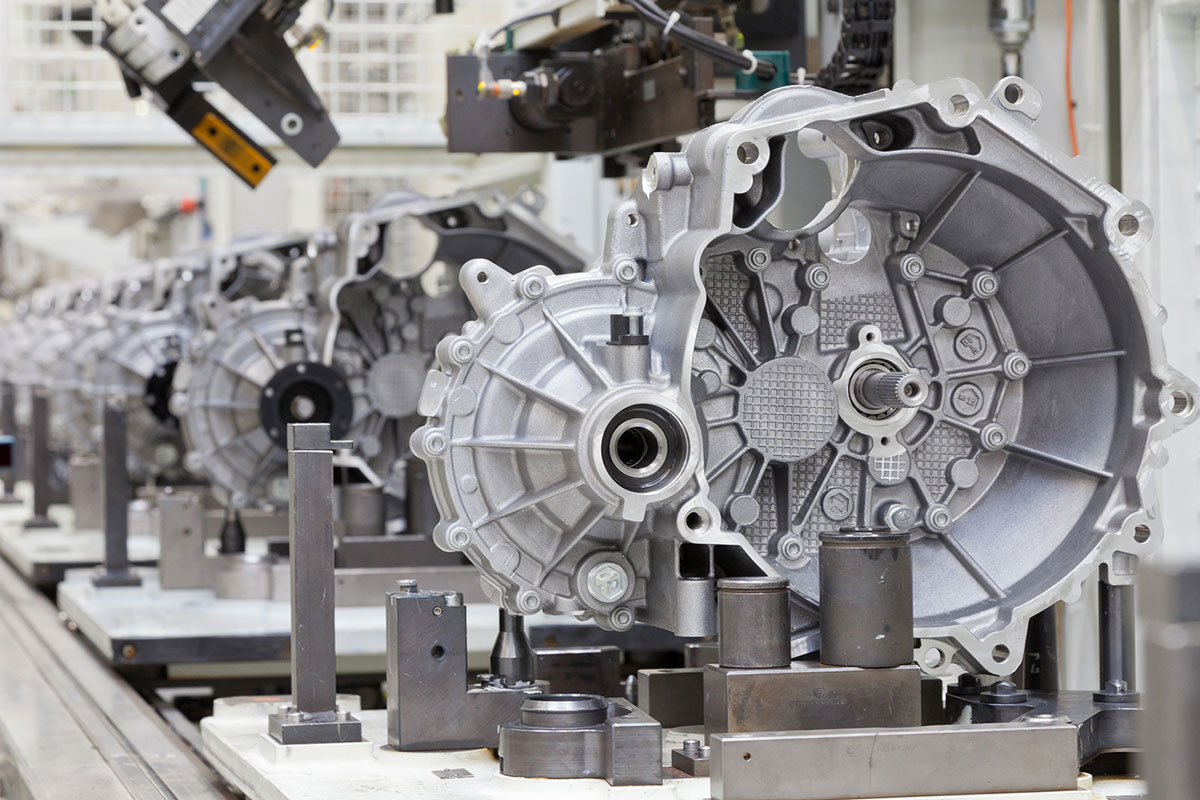

In the test at a renowned automotive supplier, rhenus EU 12-O demonstrated its strengths for gear manufacturing in the following disciplines: superfinishing, gear honing, external circular grinding and hob grinding. Compared with other products, it achieved significantly better results in terms of cooling performance, foaming behaviour and lubricating effect as well as very low evaporation losses. The specially developed grinding oil impresses with its high process reliability and contributes not only to cost savings but also to greater sustainability. Thanks to its excellent miscibility, the changeover from previously used products to rhenus EU 12-O went very smoothly.

Exemplary in terms of environmental protection and occupational safety

When it comes to environmental protection and occupational safety, rhenus EU 12-O also puts in an impressive performance. It is free of chlorine and zinc and has the lowest water hazard class (class 1). Given its low evaporation levels, it produces less oil mist, and its relatively high flash point – in excess of 200°C – also leads to greater operating safety.

rhenus EU 12-O: advantages at a glance

- High process reliability thanks to performance reserves

- Excellent cooling and lubricating performance

- Reduction of process costs, including thanks to lower servicing, filter and energy costs as well as longer tool service life

- Exemplary in terms of environmental protection as well as occupational and operating safety

Would you like to know whether rhenus Lub EU 12-O is the better alternative for your machining processes? Our lubricant experts will be happy to advise you – and our conversion service ensures a straightforward and risk-free changeover.