Rhenus Lub at the EMO 2023 – Pioneering solutions for greater sustainability and customer benefits

Reading time: 8 Min. | 08.08.2023

Many thanks for your visit at Stand E86 in Hall 6

Mönchengladbach, 4 August 2023 – EMO, the world’s leading trade fair for production technology, will be opening its doors in Hanover from 18 to 23 September 2023. Rhenus Lub is using the trade fair to present its customer-oriented solutions from the areas of metalworking fluids and fluid management for high added value and more cost-effective metalworking processes to an interested trade audience. On Stand E86 in Hall 6, the Mönchengladbach-based lubricant manufacturer will be focusing on rhenus XT 85 GREEN, rhenus TY 155 L, rhenus TU 426 and rhenus EU 12-O, modern special metalworking fluids that make a measurable contribution to more sustainable and efficient metalworking processes. In addition, the company will be presenting rhenus check&care, a web-based fluid management software for simple recording of all important measurement data for greater process efficiency and safety.

“We are looking forward to exhibiting at the EMO 2023 and to presenting our new solutions to the visitors in Hanover. With the new rhenus XT 85 GREEN metalworking fluid, the issue of sustainability is very high on the agenda for us. This water-miscible metalworking fluid contains more than 85 percent biogenic carbon. With this impressive footprint, the product is just as unique as it is powerful,” says Thomas Genz, Head of Marketing at Rhenus Lub.

Our latest products

- rhenus XT 85 GREEN: innovative technology heralds a new era of environmentally friendly metalworking fluids

- rhenus check&care: web-based software solution for optimised use of lubricants

- rhenus TY 155 L: water-miscible metalworking fluid for materials prone to staining

- rhenus TU 426: boron- and biocide-free all-rounder with very good cooling and lubricating properties

- rhenus EU 12-O: efficient high-performance grinding and cutting oil based on the GTL technology

rhenus XT 85 GREEN: Leading the way thanks to biogenic carbon

With the rhenus XT 85 GREEN metalworking fluid, Rhenus Lub is setting a new standard in sustainability. The metalworking fluid presented at the EMO 2023 is a high-performance alternative for all metalworkers who attach particular importance to more sustainable products. With over 85 percent, rhenus XT 85 GREEN contains a high proportion of biogenic carbon. The advantage: the concept uses the climate-damaging greenhouse gas CO2 as an active ingredient. CO2 is thereby converted into a usable raw material and a cyclic model is created in which CO2 is taken from the atmosphere, biologically transformed and returned to the atmosphere after use. As a result, the metalworking fluid does not lead to a net increase in greenhouse gases even after the life cycle (final thermal recycling).

rhenus check&care: Transparency thanks to real-time data transmission

Knowing the exact condition of all the metalworking fluids in use at all times improves the efficiency and safety of your production processes. At the EMO, interested visitors can test the rhenus check&care fluid management solution together with the company’s experts at an interactive terminal. The web-based software makes it easy to record all the necessary measurement data which is then available in real time. rhenus check&care can be operated without installation on terminals and without access to a company network.

rhenus TY 155 L: Highest performance for materials prone to staining

With rhenus TY 155 L, Rhenus Lub is presenting a boron-free, water-soluble, fully synthetic special metalworking fluid for efficient machining of materials prone to staining. Its high stability and long service life make it a convincing option especially for aluminium alloys, steels, titanium alloys and non-ferrous metals. rhenus TY 155 L helps to reduce material costs and shorten machining processes. A special feature: The product is HIO uncritical, qualifying it directly for machining processes in the semiconductor industry. There, the water-miscible metalworking fluid already achieved impressive results and has corresponding process approval.

rhenus TU 426: multi-purpose product for cost-optimised production

The boron- and biocide-free rhenus TU 426 metalworking fluid convinces with its flexibility of use, very good cooling and lubricating properties as well as extremely low foaming. The solution that is suitable for aluminium, stainless steel, steel and cast materials, has long-term stability and thus requires little maintenance. The metalworking fluid without SVHC ingredients and with water hazard class 1 is characterised by a lower drop in pH value compared with competitors’ products. rhenus TU 426 is suitable for turning, milling, drilling, thread cutting and grinding.

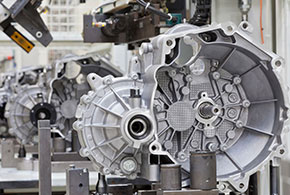

rhenus EU 12-O: process reliability with high cost effectiveness

rhenus EU 12-O is based on the pioneering gas-to-liquid (GTL) technology. The universally applicable high-performance grinding and cutting oil reduces process costs through lower maintenance, filter and energy costs as well as longer tool life. It is recommended for the demanding grinding of carbide metals and gear parts as well as for the machining of special alloys. In addition, the product sets standards in environmental protection and occupational safety with its high flash point and low tendency to evaporate. The metalworking fluid is therefore a real alternative to conventional lubricants and has already been able to prove its high performance in the production of transmission components for the automotive industry.