Premium EP lubricating greases for pelleting presses

Reading time: 5 Min. | 24.04.2018

Contents

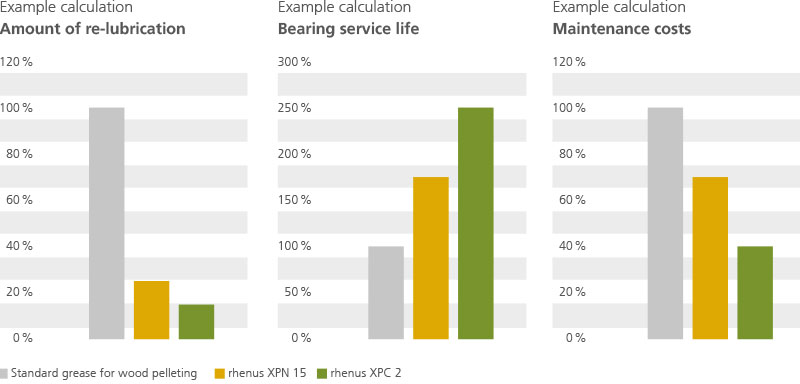

Less need for re-lubrication, longer bearing service life, reduced maintenance costs: With new hybrid technology, Rhenus Lub greases make wood pelleting more economical than ever before.

Pelleting — processing under high pressure

The transformation of wood shavings into energy-providing pellets places the highest demands on your pelleting plant; the machine‘s rollers in particular are subject to high loads. As the machine‘s powerful centrepiece, they apply enormous amounts of pressure to press the dampened shavings through holes in the steel die to form the typical rod shape of wood pellets.

As a wood pelleting company, you know that the roller bearings do not always withstand this tremendous pressure unscathed. Heavy wear to the bearings of these components and high re-lubrication requirements are costly consequences. Additional stress can be placed on machine parts by typical environmental influences for pelleting systems, such as wood dust, vibration and moisture, along with running temperatures of the bearings of up to 120 degrees Celsius.

For you as a user, finding a high-performance, corrosion-resistant and economical roller bearing grease is therefore crucial to ensure that your pelleting is financially successful.

Perfected for pelleting presses:

Special hybrid thickener technology from Rhenus Lub

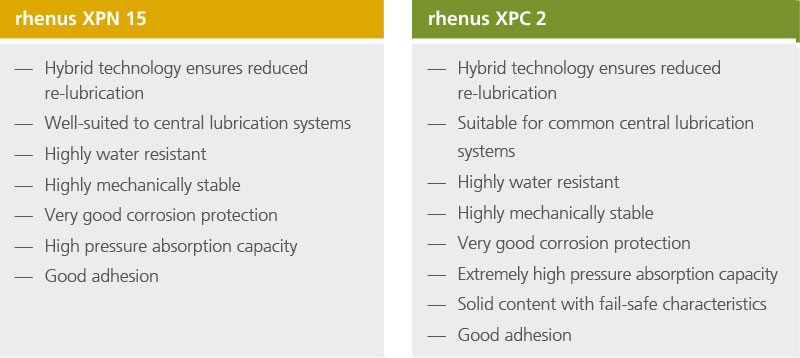

The new Premium EP greases rhenus XPN 15 and rhenus XPC 2 from Rhenus Lub are the most innovative solution for lubricating the highly strained bearings in pelleting presses. Unlike standard greases for roller bearings, rhenus high-performance lubricating greases take the best characteristics of common types of thickener and combine them with other powerful ingredients to create a completely new formulation.

Thanks to the innovative composition of rhenus XPN 15 and rhenus XPC 2 based on special hybrid thickener technology, you benefit from greatly improved performance compared with conventional lithium or calcium-thickened greases.

Semi-synthetic oil-based EP hybrid greases protect against corrosion, are water resistant and perform excellently in applications subject to extremely high-pressures. They are therefore ideal for use in the highly stressed roller bearings in your wood pelleting plant.

Press pellets more efficiently

As the example shows, with rhenus special hybrid lubricants you can massively reduce the required amount of re-lubrication in comparison with standard greases for wood pelleting, extending the bearing service life considerably and thus reducing maintenance costs:

The performance profile also allows these greases to be used in other demanding applications where bearings are subject to high loads, impacts and humidity.