The rhenus principle – focused on sustainability

Reading time: 8 Min. | 25.01.2018

Content

For us, sustainability means that ...

- we take responsibility with regard to health and safety at work.

- we rely on innovative and thus sustainable raw materials.

- social commitment and personal responsibility are also among the core pillars of a stable company.

- we invest in modern infrastructure and digital technologies to more than meet the demands of tomorrow.

These aspects all have one thing in common: even if framework conditions change, requirements change or demands increase – the sustainability principle of Rhenus Lub has a long-term effect and secures the future. Of our products, of our company, of our customers.

Proactive for people & health

Rhenus Lub is a driving force in terms of process safety and active occupational safety, health and environmental protection.

For us, the focus is on people and their health. Because in many industries it is no longer just about process reliability and maximum stability: active occupational health and safety is just as crucial for successful production. Therefore, it is a matter of course for us to also offer label-free and skin-compatible products. We haven’t just been doing this since yesterday: as early as 1991, Rhenus Lub was one of the first companies in the lubricant industry to launch amine- and boric acid-free cooling lubricants on the market in the spirit of active employee protection.

Especially with regard to occupational safety and health protection, we are a driving force and do not just comply with existing regulations: In our research department, we develop lubricants that often even go beyond the legal requirements and can therefore be used in the longer term and are future-proof. Our cooling lubricant rhenus FU 800 is an example of this. The fluid actively protects the health of employees through an innovative formulation and the absence of ingredients that pose a health risk. Because for sustainable production, the health of the employee is an essential success factor.

Careful use of the environment & resources

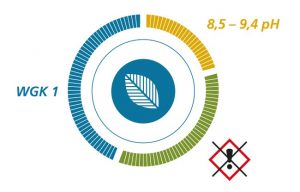

In industries such as agriculture and forestry, rail transport, the construction industry, port technology, open-cast mining or tunnel construction, lubricating greases used can quickly get into the soil or water. For a careful and sustainable approach to nature, we at Rhenus Lub therefore offer numerous environmentally friendly products that can be easily and completely degraded by biochemical processes in the soil or in water areas. In this way, we actively support our customers in carrying out their operations even in ecologically sensitive areas.

At the same time, an intact environment also requires the careful use of resources – a task that we have deeply anchored in our research mentality. We recognise market trends early on: Which raw materials are in short supply? Which ingredients will soon be banned by law? We develop alternatives at an early stage so that you will continue to receive products of the same quality in the future. For sure – without bottlenecks, without a drop in performance.

Personally responsible & socially committed

We are a typical medium-sized family business – a great advantage: it allows us not only flexibility and short reaction times, but also a long-term and thus sustainable orientation. We are not dependent on short-term price changes, as they can be triggered by investors – a foundation that customers and employees feel.

More responsibility worldwide within the framework of the UN Global Compact initiative

As an internationally active company, we also bear global responsibility. In the UN Global Compact initiative, we advocate for more corporate responsibility within our sphere of influence, even beyond national borders – with the overarching goal of making the economy more sustainable and fairer. But Rhenus Lub also bears responsibility locally: As an important employer, we strengthen Mönchengladbach as a business location. On the other hand, we are always involved in social projects around our company headquarters – for more justice and sustainable development in the region.

Our industry: networked & digital

As an innovation leader, our qualified employees develop and produce under the most modern conditions: With manufacturing technologies that are always state-of-the-art, we can produce lubricants with the best possible performance for our customers. Our grease factory – one of the most modern in Europe – plays a major role in this. And with the first step towards the Smart Factory, we completed an important stage towards optimised production in 2015: the sensible use of data and the analysis of individual algorithms enable us to control the interactions in complex production even better and to control them precisely down to the smallest detail. This optimisation has a direct positive impact on the development and manufacture of our products.

But processes geared towards Industry 4.0 are also becoming increasingly important for our customers. With the FluidSafe LubControlSystem, we have developed a device that monitors cooling lubricants online. It provides data that can be retrieved in real time and contributes significantly to the digital networking of the process. Because what applies to our production facilities also applies to our customers’ businesses: With state-of-the-art technology and digitally networked production, we are shaping the future of our industry together.