Our wide range of metalworking fluids offers solutions for specialised areas of application as well as high-performance all-rounders. The entire spectrum of metalworking fluids and neat oils from Rhenus Lub are the product of so much research, development and experience that we can supply you with the ideal lubricant for your area of application in metalworking. Whether for drilling, grinding, milling, punching or cutting, our application-specific rhenus metalworking fluids ensure maximum workpiece quality and a considerable reduction in tool wear.

Industrial metalworking fluids made in Germany

Requirements in industry are constantly increasing, with greater automation and increasing performance of tools, machines and systems, as well as novel materials.

Our goal is to develop the optimum product for every application. Around the world, we have some 270 employees working towards this objective – 20% of whom work in research and development.

Our metalworking fluids are the best choice for safe and cost-efficient metalworking.

High-quality metalworking fluids and metalworking oils are a key factor in the success of any production process. They protect machinery and tools from increased wear, ensure optimum dimensional accuracy and surface quality – all with an impressively low consumption.

Metalworking fluids are needed in almost every production environment and therefore cover a wide range of requirements and properties:

- stability

- material compatibility

- skin-friendliness

- cooling and lubricating effect

- long service life

- low corrosion and more

Choosing the correct metalworking fluid is therefore vital when it comes to ensuring trouble-free applications. We’ll be delighted to help you make the right choice – go to product finder!

We work constantly to refine the range of rhenus metalworking fluids in close collaboration with universities and research institutes in order to meet the growing production requirements of a multitude of industries and applications.

Metalworking fluids

Water-miscible

- Amine- and boric acid-free metalworking fluids

- Boric acid-free metalworking fluids based on alternative amines

- Two-component metalworking fluids

- Multifunctional products

- Magnesium machining

Metalworking fluids

Neat oils

- Excellent cooling performance

- Increased cutting speed and material removal rates

- Less wear and lower maintenance costs

- High surface quality and dimensional accuracy

- Low consumption

- No risk of grinding burn

- Safety thanks to high flash points

Frequently asked questions

What constituents and additives are there in metalworking fluids?

A neat oil only requires a few individual constituents because it doesn’t have to account for the presence of water – with all its influencing parameters. The essential base component is the oil (mineral oil, vegetable/synthetic esters), which is enriched with polar active ingredients and chemically active EP additives in order to improve cutting performance. Further additives (anti-fog additives or antioxidants) improve shelf life and the behaviour of the cutting oils in the machining process.

What is the role of metalworking fluids?

Metalworking fluids have two main roles: to achieve a cooling and lubricating effect and to remove chips and other waste products. The fluids are used in a wide range of machining processes, including turning, drilling, milling, broaching, grinding, honing and lapping.

In water-miscible metalworking fluids, the cooling effect depends almost exclusively on the water, whereas in neat oils it depends on the viscosity. The lubricant effect, on the other hand, is strongly influenced by the type and structure of the metalworking fluid. Lubricant (polar) and chemically active (EP = extreme pressure) additives are used to adapt the lubricating effect and pressure absorption capacity to the machining process.

How do I find the right metalworking fluid for my area of application?

The choice of the right metalworking fluid depends on numerous complex factors relating to the area of application. We’ll be delighted to help you reach a decision as part of an on-site visit.

Particularly relevant factors in choosing a metalworking fluid include:

- type of machine tool

- material to be machined

- type of tools

- cutting speed, feed rate

- dimensional accuracy, surface quality

- metalworking fluid pressure and quantity

- type of filtration

- temperature of metalworking fluid

Signs of a well-adapted metalworking fluid

- Reliable corrosion protection for machine and workpiece

- No discolouration of the machined materials

- Good residue behaviour, especially in the splash zone

- Good washability of the MWF film that inevitably remains

- Good rinsing and wetting properties

- Impeccable filtration properties

- Dirt removal capability in machines with filter

- Dirt settling properties in machines without filter

- Rapid air separation and foam degradation

- Ability to withstand thermal loads

- Easy separation of tramp oils

- Relative insensitivity to different water qualities

- Ageing resistance and stability

What do I need to bear in mind when using metalworking fluids?

With adequate care and sensible handling, the safe use of metalworking fluids is no problem. Key factors include:

- Safe storage and labelling

- Creation of a register of MWFs and hazardous substances

- Easy-to-understand operating instructions

- Plans for cleaning, preservation and maintenance

- Avoidance of skin contact

- Water-repellent working clothing

- Immediate changing of soaked clothing

- Regular hand washing with subsequent skin care

- No further use of cloths contaminated with MWF constituents

- Avoidance of aerosols and vapours

- Closed machine technology

- Splash guards

- Avoidance of foreign matter in MWF cycle

- Protection against mechanical parts, tramp oils, waste, cleaning agents, dust

Devote your full attention to your production process while our rhenus lubrineering specialists take care of the rest.

What problems can arise during the use of metalworking fluids?

Problems are most likely to arise with metalworking fluids if the wrong product was chosen or maintenance was not carried out correctly.

The following factors, for example, can detract from the performance of a metalworking fluid:

- quality of the mixing water

- type of materials

- construction and maintenance devices of the machine tool

- negligence by machine operators

The most common problems with metalworking fluids are:

- unwanted foaming

- unpleasant odour

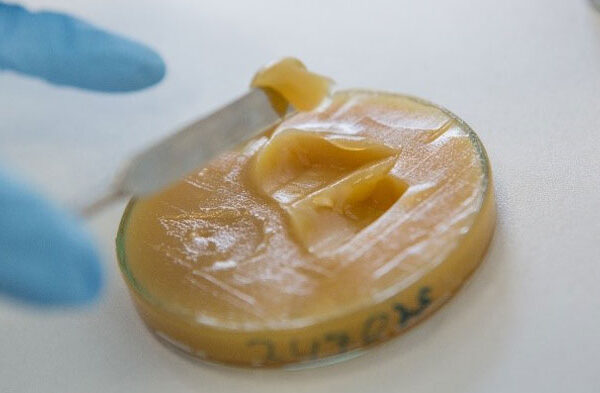

- germ formation and fungus infestation

- rust appears on the workpiece or machine

- paint flakes off or seals swell

- reduced lubricating effect

- changes in demulsifying behaviour

- reduced surface quality

- higher tool wear

- discolouration of the workpiece

- staff complain of skin irritation

- deposits and tramp oil in the MWF

- unpleasant fumes irritate the respiratory tract

Troubleshooting often requires only a small change to the machine, the process or the habits of the machine operators – and the metalworking fluid works perfectly again. If problems persist, a laboratory analysis of the MWF provides valuable insights.

How often do metalworking fluids need to be checked?

Regular inspection of metalworking fluids is essential in order to preserve the performance of your MWF in the long term.

The appearance and odour of the MWF must be checked on a daily basis. According to TSRG 611, the concentration, pH value, nitrite and bacteria count must also be checked at least once a week. Depending on the constituents of the MWF, further tests are needed at varying intervals.

Routine on-site checks are accompanied by laboratory analyses in order to further monitor the emulsion. The respective scope of analysis and the analysis intervals vary, depending on the metalworking fluid, the system and the procedure.

Further information on MWF monitoring can be found here:

How often do metalworking fluids need to be changed?

There are no standardised intervals for changing metalworking fluids, as the service life of an MWF depends to a large extent on close monitoring and regular maintenance by the user.

MWF change intervals range from a few weeks to several years.

What health aspects must be taken into account in the handling of metalworking fluids?

Adverse health effects of handling metalworking fluids can be reliably avoided with proper handling and maintenance.

Metalworking fluids from Rhenus Lub are particularly outstanding in this respect. Many of our products are free of amines, boric acid and formaldehyde and have low pH values.

In other MWFs, we reduce the quantity of potentially harmful constituents and additives to the bare minimum. The raw materials used are subject to careful monitoring. Accordingly, our products are among the most skin-friendly metalworking fluids in the industry.

The main area of use for MWFs is the metalworking industry. Although exposure is already reduced considerably by a high degree of automation in conjunction with appropriate protective measures, users should nevertheless avoid long-term and intensive skin contact with metalworking fluids. It is also important to ensure reliable protection against contamination of the MWF by foreign matter, for example.

The careful handling of working substances and rigorous care of both substances and skin after work is complete are important in order to ensure that staff enjoy optimum protection even where there is regular contact with metalworking fluids.

Find out more about “Metalworking fluids and skin care”!

Are there any environmentally friendly metalworking fluids?

Rhenus Lub offers a whole series of environmentally friendly metalworking fluids. Around 85% of our MWFs are classified in the lowest water hazard class (WGK 1).

Users benefit from significantly lower restraints on transport, storage and handling, as there is less risk of environmental and groundwater contamination. Find out more about the innovative products from Rhenus Lub.

Contact us if you have any further queries!

Impuls News

The latest posts and expert articles relating to metalworking fluids, special greases and new research findings from Rhenus Lub.